MAC-AG is a super solution solve your important problems. The advanced machinery combination allow you to do any shape cutting, grinding, drilling and cut-out.

This solution give you superior competitiveness on some special products processing.

Super velocity compared with other SOLUTIONS.

1-6mm thickness glass with any shape and cut-out.

perfect pencil edging without square and shapes on one line.

Wonderful accuracy and finishing for cutting, breaking, edging, drilling and cut-out

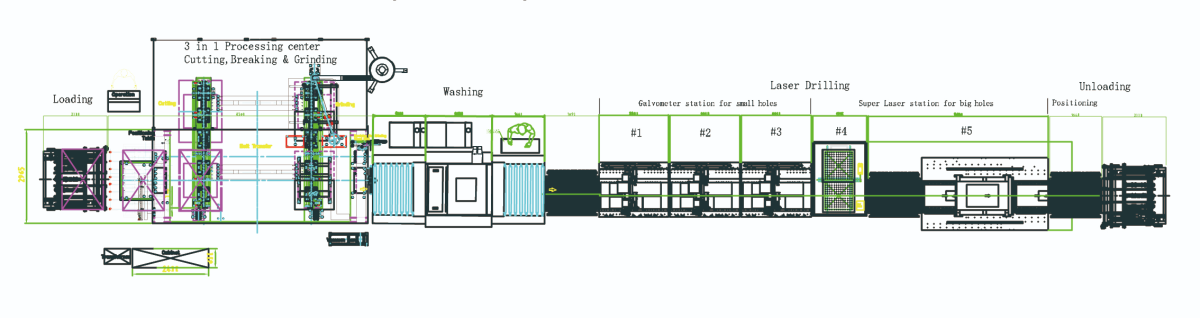

The solution is including following machines with scientific combination.

Automatic loader with cycle time 6-8 seconds per piece.

4-in-1 -Processing Center with independent stations for automatic cutting, breaking, pencil edging and drilling, Pencil edging for different shape and R-shape corner.

One or two heads drilling station according to different products.

High performance Washing-Drying Machine at 15m/min.

MAClas laser drilling Galvometer with green laser and High speed laser cutting machine for cut-out.

The 4-in-1 processing center is revolutionarily introduced to the APPLIANCE GLASS PROCESSING. It is fast, reliable, high performance finishing and automation, space economic and help to build very clean production environment.

The line need very delicate design with high speed and reliability. MAC specially recommend the MAClas drilling series. It is the perfect solution and commonly used on solar glass, appliance glass, shower door etc.

For the hole less than 50mm, we have green laser galvo technology while more than 50mm to 150mm, we use high speed laser and the exclusive splitting technology to get the perfect whole finishing. The high speed, superior performance and dramatical production consumables saving make it the future for the glass drilling and cut.

The Story of MAC-YUGONG and BOYU GLASS began in 2021. BOYU GLASS, located in Nantong, is one of the region’s leading manufacturers of high-end door and window glass. <BR> Mr.Liu, the founder of BOYU brought 4,000m2 workshop la...

MAC GLASTECH & AUTOMATION CO.,LTD. provides laminated glass solutions, consisting of two or more glass panes bonded together with interlayer films. Bulletproof glass is one of our specialized offerings. With extensive experience serving clients w...

ASRS is to use a set of hardware and software combination of the system to replace the warehouse logistics movement, that is, the warehouse transceiver through automated equipment to achieve, first of all have to make a three-dimensional s...

Low-E is the abbreviation of Low-emissivity, which refers to low emissivity, that is, a higher far-infrared reflectivity, so Low-E is also called low-emissivity glass. Low-E glass is divided into single-silver, double-silver and triple-silver Low-E g...

Category

Copyright © 2025 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy