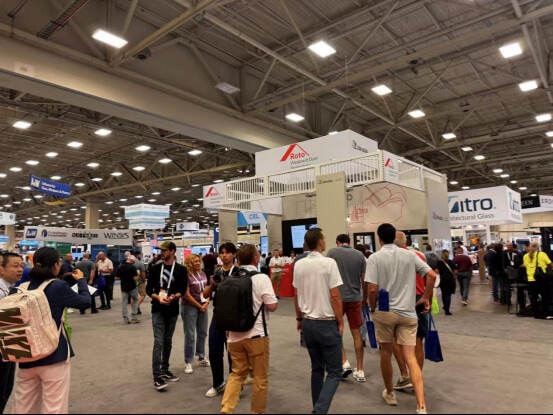

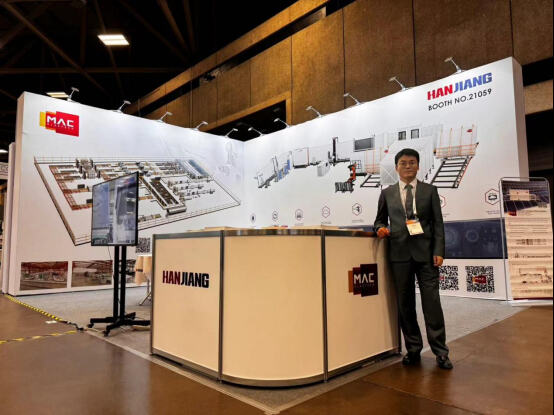

The 21st GlassBuild America was successfully held in Dallas, marking the largest event in the past 16 years. This year also marked the second time that MAC-HANJIANG participated in the exhibition together.

The Americas sales team attended, showcasing a diverse range of advanced glass deep-processing software systems and automation solutions.

The show allowed us to engage with new and existing customers from every corner of the U.S., along attendees who traveled all over Canada, Mexico, Central America (and even Colombia). We showed a lot of automation practice cases and insulated glass larg-scale project videos from MAC-HANJIANG. The automation manufacturing line construction projects have fundamentally solved some difficult issues for those glass deep-processing enterprises then are processing architectural glass managing the production orders and labors. Note: At the time, many large-scale deep-processing companies were quite interested in our solutions.

HANJIANG started exporting the IG solutions since 2005 and installed its first insulated glass production line in California. Over its near 20-year history, it has faithfully served the North American market for almost two decades forging many customer relationships and seeing those customers see tremendous growth. Hanjiang presents various excellent insulated glass production solutions for different segments, such as residential and commercial IGU, Jumbo IG solutions of entire range size, quintet spacer options,high speed production lines even specialized glasses by our abundant service experiences to deeply understand what the market demands. And, 20 years experience of glass production management with MAC Software. MAC-HANJIANG shake hands to install hundreds of fully automatic glass deep-processing lines successfully in the architectural, automotive, home appliances and solar energy areas. As entering the North American market just two years ago, MAC-HANJIANG has successfully landed a large automation project for a full architectural glass plant to be installed and commissioned by mid-2025.

The market has completely turned around with MAC-HANJIANG automation solutions. With a series of integrated system software and hardware,the full automatic glass deep processing process has been realized, that is, the optimization of production order, reduction in manual intervention to improve productivity and product quality by MAC. That means all pieces of the process are working a lot better. This also helps in reducing manual operations, and saving on labor costs as well as reduce the error caused during production due to human touch. Conversely, improved production efficiency enables companies to answer market demands much faster, reduces delivery cycles and boosts customer satisfaction.

In addition, MAC automation solutions allow deep-processing companies to better adapt and produce at will by quickly changing the production line settings according to different requirements of orders in order for these customization needs can be met. This flexibility allows companies to better use their production resources as well more efficient production scheduling. In general, MAC automation solutions in the glass deep-processing industry have led companies to intelligent manufacturing and give enterprises a competitive advantage within the fiercely competitive market.

Copyright © 2025 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy