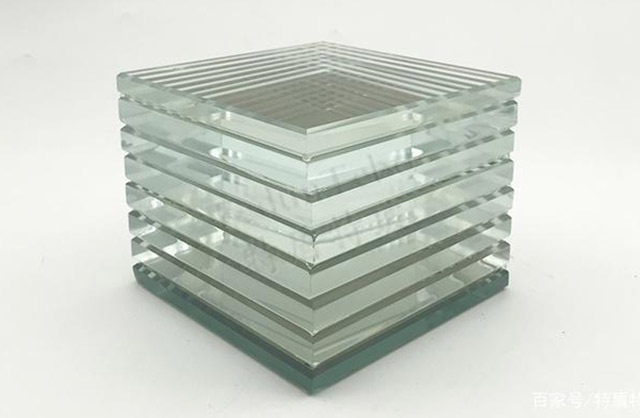

Bullet-proof glass, also known as ballistic glass, is a kind of Laminated glass production, composite material with high security performance.

Basic Information

Composition: It is usually made by bonding a load-bearing glass layer, a transition layer of plastic material, and a protective glass layer under high temperature and pressure.

Thickness: Generally, it ranges from 7mm to 75mm, and some special ones can be up to 136mm.

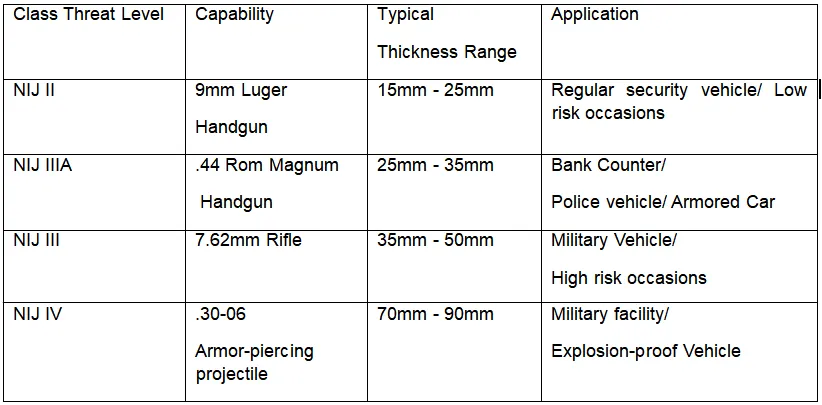

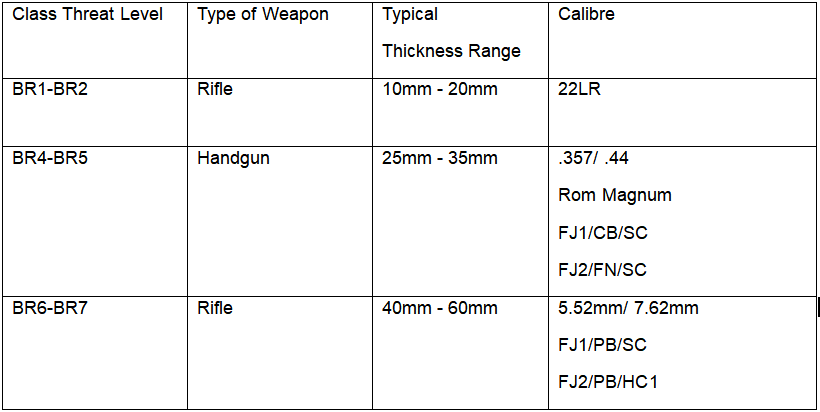

The following is some standards for bullet-proof glass

US NIJ STANDARD

EU EN STANDARD

Processing Methods:

How to make bullet-proof glass production? MAC offers you the following two solutions.

1、Use pressing machine to handle directly, this method requires high structure toughness and flexibility of pressing machine.

MAC offers the pressing machine can deal with ≦100mm thickness bullet-proof glass production (with special designed recipe). MAC has rich experience with bullet-proof glass processing, provide solutions for many customers all over the world.

Please see the below pictures as your reference.

RE1

RE2

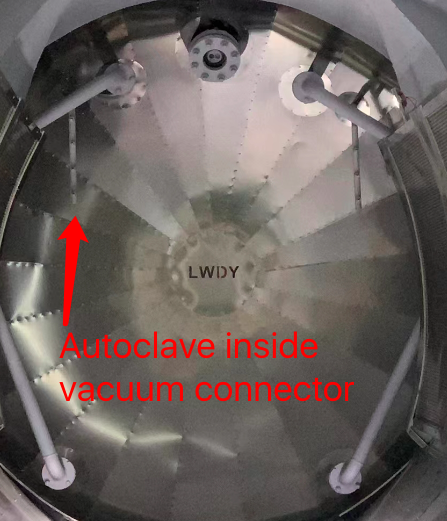

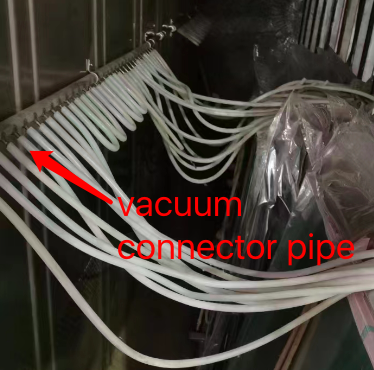

2、Another method is to use vacuum system. In order to use this function, the autoclave needs to configure the vacuum pump connectors flange outside, and vacuum pipe connector inside.

Outside

Inside1

Inside2

Now we can start the vacuum processing procedure.

Some accessories needs to be prepared as following:

The Accessories list:

Prepare two tables, one table is for the laminated glass assembly manually.

Another table (the table is better soft to protect the glass) is for packing the glass inside of the vacuum film.

Packing operation steps are as following:

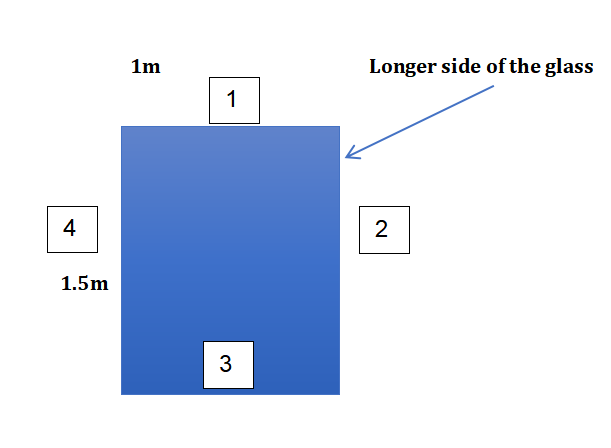

Step 1, tailor one piece of perforated release film or vacuum film, ensure the width is around triple size of the laminated glass thickness, the length is the glass length(side 2 or side 4), longer side of the glass (if all sides’ length are same, it’s better to choose the vertical direction of the tempering machine roller, for better air flow outlet). Use flash tape to fix the perforated release film or vacuum film on the side of the glass (side 2 or side 4), you can pack the other side of the glass use same workflow. Normally this operation only needs to fix the side 2 and side 4 (the longer side of the glass), but it can also fix all the sides of the glass for quality concern.

Step 1

Step 2, tailor one piece of Porous strip, ensure the size is same, repeat step 1.

Step 2

Step 3, tailor one small piece of Porous strip, and use flash tape to fix it on the glass.

Step 4, put the laminated glass inside of the vacuum film, ensure the vacuum film size is 10cm bigger than the glass size for all sides. And then make one hole on the vacuum film according to the step 3 porous strip position to fix the vacuum connector. The vacuum connector quantity can be adjusted according to glass size.

Step 4

Step 5, use the sealing device to seal the vacuum film.

Step 6, processing vacuum procedure outside of the Autoclave.

Step 7, push the glass production into the Autoclave, to reach the required temperature and pressure.

Copyright © 2025 China MAC GLASTECH AND AUTOMATION CO.,LIMITED. All rights reserved — Privacy Policy